Not all stones are created equally. A stone’s resistance to weathering and staining depends on the minerals that compose the stone, the cement that binds the stone together, and the amount of open pore space (porosity) between the grains in the stone.

Not all stones are created equally. A stone’s resistance to weathering and staining depends on the minerals that compose the stone, the cement that binds the stone together, and the amount of open pore space (porosity) between the grains in the stone.

Crystalline rocks like granites contain resistant minerals with tight interlocking grains and very low porosity. Consequently, granites are some of the most durable building stones. Sedimentary rocks like sandstone and limestone vary greatly and are more difficult to evaluate. Some are very resistant to weathering while others will deteriorate much more quickly.

Stone durability can be evaluated in several ways. A close inspection with a rock hammer can give you a pretty good sense of hardness. There are also a variety of laboratory tests that can help. In addition, there are many stone treatments that enhance a stone’s durability and stain resistance.

Freeze-Thaw Damage

Freeze-Thaw Damage

Repeated freeze-thaw cycles can damage some porous sandstones and limestones. Water that penetrates the pore spaces of a stone expands when it freezes and can cause spalling. The best way to protect against freeze-thaw damage is to use a stone with a low porosity; however, this isn’t always possible. Fortunately, there are stone treatments that repel water and enhance the durability of stone. Products like ProSoCo H40 and H100 are water repellant treatments that strengthen stone by depositing silica into the pore spaces.

Salt Damage

Salt Damage

Salt damage can occur in porous stones that are exposed to salty water from surface splash, salty coastal air, or from soil moisture. When salty water penetrates a stone, salts crystallize in the pore spaces and can cause spalling and discoloration. Salts can enter through the face of the stone and mortar, by getting behind poorly mortared stone, or by wicking upwards from shallow soil moisture. Stone treatments such as Prosoco Salt Guard repel water and salt; however, they can only be applied to the face of a finished stone wall or the surface of a floor. They are breathable treatments and can not protect stone from water that gets behind or wicks up from beneath the stone.

Oil and Stain Repellants

Oil and Stain Repellants

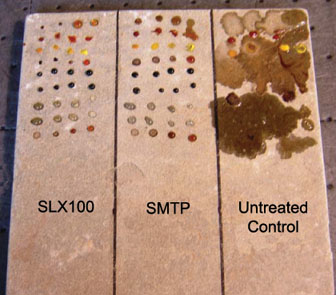

Oil and food stains can penetrate some stones (particularly sandstones and limestones) and can be very difficult to remove. Oil and stain repellants, like ProSoCo SLX100 and Stone Masonry and Tile Protector (SMTP), penetrate the pore spaces and help stone resist staining. The image at right shows the difference in stain penetration between treated samples and an untreated control. Water repellants also reduce water penetration and therefore reduce the potential for freeze-thaw damage.

Color Enhancers

Color Enhancers

Sometimes the natural color of a stone isn’t exactly what the client, architect, or designer desires. In many cases, color enhancers can be used to deepen the color of stone as well as provide water and stain repellancy. Different enhancers provide varying amounts of color change. Shown at left are the color changes produced by ProSoCo Gloss ‘N Guard, Gloss ‘N Guard WB, and Paver Enhancer.

Stone Cleaners

Stone Cleaners

In most cases stone should be thoroughly cleaned after installation. The most common cleaner used on masonry stone is muriatic acid diluted with water. Muriatic acid removes mortar stains and other calcium deposits as shown in the image at right. However, muriatic acid is generally not appropriate for limestones and marbles because the acid can etch or discolor the stone. Other cleaners, such as ProSoCo’s Safety Klean, are safer to use on limestones and marbles. It is always best to test muriatic acid, or any other cleaner, on a stone sample before use.