Sandstones are one of the primary types of stone used as masonry stone. They occur in many settings on all continents and have been used as a building stone since the earliest days of recorded human history.

Magnified view of the Flatwillow Sandstone.

Geology of Sandstones

Sandstones are generated by the erosional breakdown of pre-existing rock. The pre-existing rock may have been igneous, metamorphic or sedimentary, depending on the location. Sandstones are most commonly created when mountains are uplifted, which leads to the erosion and subsequent deposition of sandstones as well as shales and siltstones. Most sandstones are deposited as marine sediments (in the ocean); however, they are also deposited in rivers and lakes as well as by wind (sand dunes).

Sandstones used in the building stone industry are composed mostly of quartz grains with lesser amounts of other minerals. Quartz is more resistant to weathering than most other minerals and it tends to survive and be concentrated by the erosion and transportation processes that deposit sandstone. The grain sizes of sandstones range from barely visible by the naked eye to large pebbles. Geologists break sandstones down into many categories (arkose, greywacke, conglomerate, etc.); however, in the stone industry they all fall under the category of sandstone.

All sandstones were initially deposited as loose sand in the water or on the surface of the earth. As the sand is buried by later sedimentary deposits, it undergoes compression and cementation. Compression, due to the weight of the overlying sediments, pushes the sand grains closer together, reducing the amount of open pore space. Cementation occurs as groundwater circulates through the buried sand deposit and precipitates out minerals in the pore spaces between the sand grains. Most sandstones have been buried thousands of feet below the surface by younger sediments, only later to be exposed at the surface again by erosion of the overlying rocks. In general, the deeper a sandstone has been buried, the more it has been compressed and cemented. The more well-cemented a sandstone is, the more desirable it is as a building stone.

Sandstone Colors

Sandstones range in color from nearly white to almost black, although most are in the gray/tan/brown range. The color is determined by the types of mineral grains that comprise the sandstone and the type of cement that binds the sand grains together. Light colored sandstones are usually predominantly composed of quartz grains and are cemented with either silica or calcium carbonate. Darker sandstones usually contain a wider variety of mineral grains. Red sandstones, which are common in the southwestern U.S., get their red color from iron oxide cement.

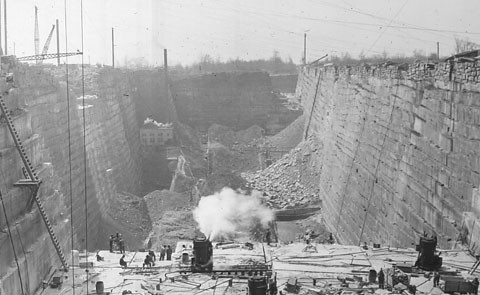

Berea Sandstone

Sandstones have been quarried commercially throughout the United States at many locations. The well-known Berea Sandstone quarries in Ohio (shown at right) have been a major source of building stone in the eastern U.S. since the mid-1800’s and some of these quarries are still in operation. The Berea is somewhat unique because it has very consistent grain size and can be worked in all directions due to its relative lack of bedding planes. In the quarry business this is called a freestone.

Brownstone

Another sandstone that has been widely used in the U.S. is Brownstone, which was quarried extensively in the 18th and 19th centuries around Portland, Connecticut. These quarries provided stone for countless buildings in New York city, many of which are now called “brownstones.” Brownstone quarrying was a huge industry, particularly in the mid- and late-19th century, but dwindled in the early 20th century. In the 1930’s a hurricane swept up the east coast of the U.S. and flooded the quarries, most of which never reopened. One brownstone quarry (Portland Brownstone Quarries) started operations again and now provides brownstone mostly for restoration work.

Flagstones

Flagstones are flat stones that split into thin layers and are commonly used for paving. Many of the flagstones quarried around the world are sandstones. Since sandstones are deposited in layers, they can sometimes be split down into sheets ranging from 1″-3″ thick. At flagstone quarries, thick slabs of sandstone are extracted and then split down with chisels to the desired thickness. In the U.S., flagstones are produced in Pennsylvania, Tennessee, Oklahoma, Colorado, Arizona, Montana as well as other states. The flagstone shown at right is Frontier Sandstone, quarried in Montana.

Sandstone Physical Properties

The physical properties of sandstones vary more than any other common building stone and this affects their resistance to weathering. The key factors controlling the weather resistance of a sandstone are the amount of open pore space and the type of cement that binds the sandstone together. The density of the commonly quarried sandstones (130-165 lbs/cf) is less than most igneous and metamorphic rocks because of the open pore space between sand grains. The open pore space in a stone is measured by an ASTM method called absorption (click ASTM for an explanation of stone testing). Absorption values for sandstones are preferably less than 6%, and the lower the better, with the best sandstones having absorption values around 1%. Water penetration into sandstone can lead to freeze-thaw deterioration, along with other weathering problems. Many sandstones that were used historically in the U.S. don’t stand up to weathering very well due to water penetration.

Sandstones are some of the most beautiful and interesting building stones; however, they were not all created equally. A little testing and little common sense will go a long way in choosing an appropriate sandstone for a project.